TPW created a 100K cleanroom level test environment, and our software and hardware test environment is at automotive device standards as a means to maintain quality. We offer professional finished product testing services and provide a variety of machine equipment platforms, including burn-in systems and tape and reel services. We use test programs to simulate integrated circuits withstanding all possible conditions, including high temperatures, low temperatures, and other harsh environments, to ensure that the quality of the integrated circuits meets customer requirements and market demand.

TPW

can provide test environments from minus 55℃ to 130℃ simulating integrated circuits in high temperatures, low temperatures, voltage instability, high or low voltage, and other harsh environments and general conditions to test whether they are working conditions are within specification ranges. TPW also offers highly automated and artificial intelligence operating system testing to meet customer product quality and on-time delivery requirements. Customers are always satisfied by our professional testing services.

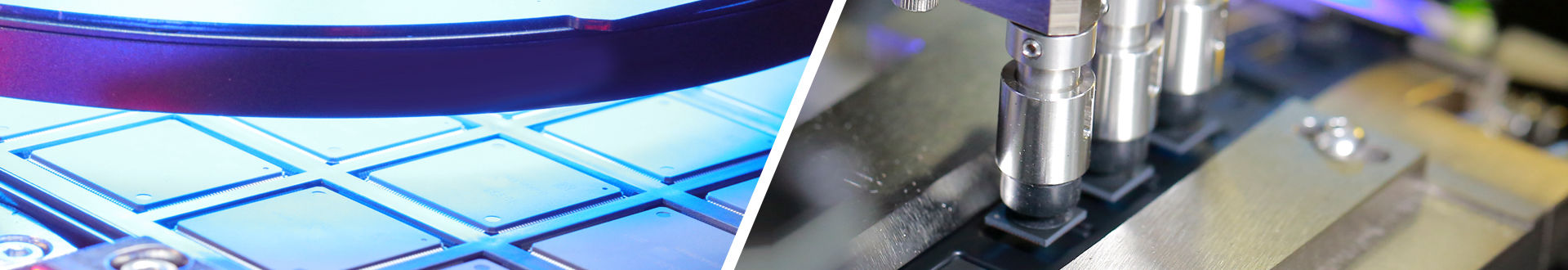

Before the functional test in the integrated circuit's back-end process, products will undergo a pre-burn test in a pre-burning furnace, placing them in high-temperature, high-voltage, and high-current environments, so that the characteristics of test products with shorter life cycles can be exposed earlier during the process, specifically the reliability and stability of product function operations. Therefore, a series of product function tests are performed in specific test environments (including high temperature, high voltage, high current) at specified times to screen out products with unstable functions.

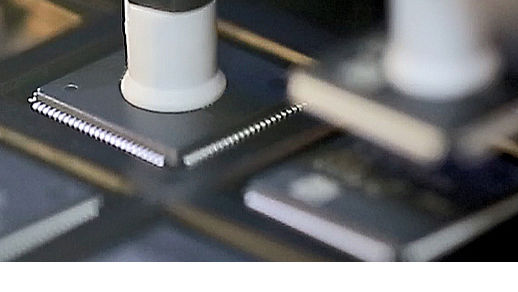

TPW also equips integrated circuit loading test board equipment with optical image detection functions before burn-in, avoiding the reverse feeding of integrated circuits.

A lead scan is the automatic inspection of the shape and positive print of the integrated circuit. TPW has a highly automated and artificial intelligence operating system. Optical measurement and inspection instruments check whether the printing or patterns are accurate, whether there are defects, and whether the pins are regular to pick out defective products. The defective products usually picked out by the instruments will be manually repaired and re-tested and entirely re-inspected to meet customers' requirements for product quality and on-time delivery.

TPW is equipped with a highly automated and artificial intelligence operation assistance system. The automatic optical measurement and inspection instrument is used for direct perspective shooting and inspection before tape operation. When the integrated circuit is reversed, or there are bent feet and faulty pins, the machine will automatically pick out the defective products, thus ensuring product quality before the tape and reel sealing operation. We can provide complete services for various integrated circuit models and sizes according to customer needs. After appearance inspection completion, the integrated circuit test is reeled to meet end customers' needs and increase customer satisfaction.

.